In the domain of DIY projects, having the right instruments and materials can make all the distinction. One often overlooked yet remarkably flexible substance is silicone sealant. This exceptional item serves as a secret weapon for both veteran professionals and passionate amateurs, offering a myriad of uses that can enhance your remodeling tasks to a completely fresh sphere.

From sealing spaces and fissures to creating a moisture-proof protection, silicone sealant is an essential component in any set of tools. Its elasticity and strength make it appropriate for a wide range of uses, whether you're engaged on waterworks, kitchen enhancements, or just looking to weatherproof your environment. Grasping the multiple functions of this incredible sealant can equip you to manage your assignments with certainty.

What is Silicone Sealant?

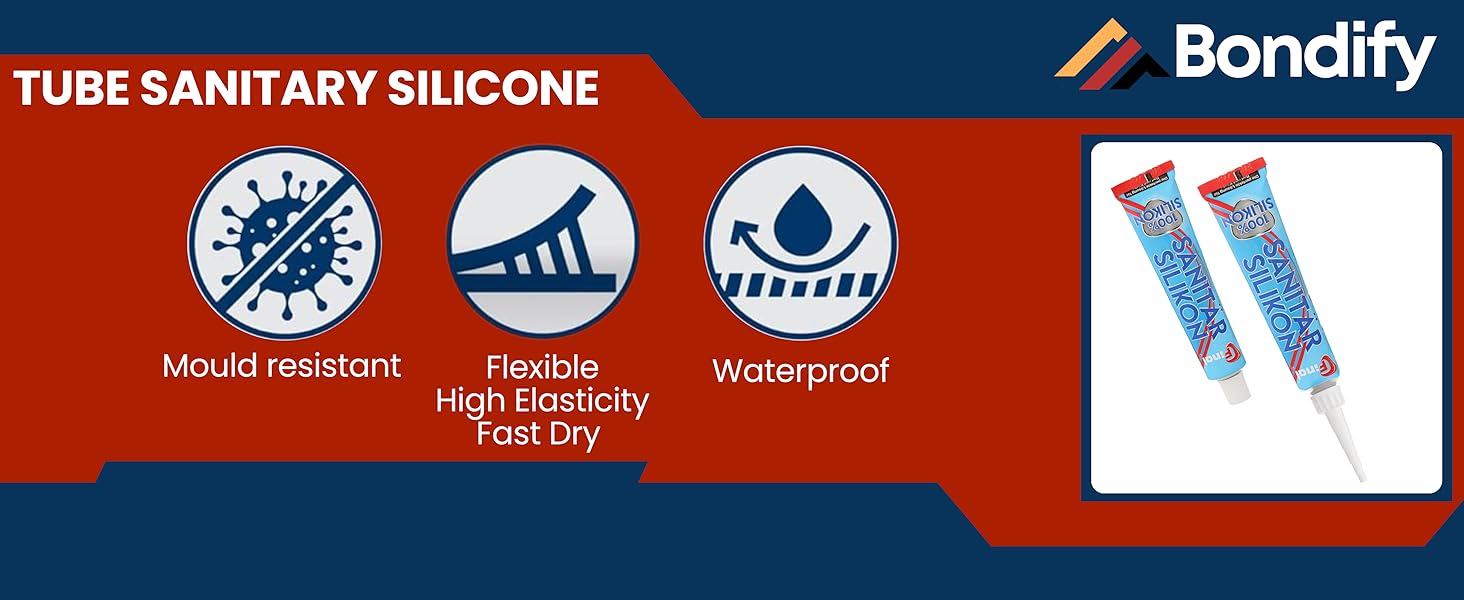

Silicone sealant is a adaptable substance frequently utilized in building and renovation projects. It consists of a man-made compound derived from silicone, a polymer that exhibits outstanding flexibility, durability, and defense to moisture, heat, and chemicals. Its unique properties make it appropriate for a variety of applications, including sealing gaps to providing waterproof barriers.

A major of the key benefits of silicone sealant lies in its ability to bond to numerous surfaces, including glass, metal, wood, and plastic. This makes it a preferred choice for both indoor and outside use. Regardless of whether you are filling in cracks around windows, sealing joints in bathrooms, or protecting against water leaks in kitchens, silicone sealant offers a reliable solution that endures over time.

In addition to its sealing capabilities, silicone sealant is available in diverse formulas and colors. This facilitates customization based on the specific needs of a project, whether matching the sealant to existing surfaces or choosing a specific type for high-temperature environments. Thanks to its ease of application and strong performance, silicone sealant is truly a secret weapon for anyone aiming to tackle DIY projects successfully.

Benefits of Using Silicon Sealant

One of the key benefits of using silicone sealant is its outstanding flexibility. Unlike traditional sealants, silicone can expand and contract with temperature changes, making it perfect for areas that experience expansion. This attribute ensures that seals stay whole and effective over time, preventing leaks and air leaks in your house or workshop. Whether you are closing around windows, door frames, or in restrooms, silicone sealant adapts easily to different conditions.

Another major benefit of silicone sealant is its waterproof properties. Once cured, it creates a strong barrier against moisture, which is essential in areas susceptible to water exposure such as kitchens and restrooms. This feature not only assists protect against moisture damage but also prevents the growth of mold and mold spores, contributing to a safer living environment. The lifetime of silicone sealant means you can rely on it to last for many years without the requirement for frequent replacement.

Finally, silicone sealant is extremely versatile and easy to work with. It can stick to a broad range of materials, including glass, metal, plastic, and timber. This versatility makes it suitable for many DIY projects, from crafting and fixes to home improvement projects. Additionally, its usage process is simple; it comes in tubes that fit regular caulking guns, allowing for accurate application and a clean finish. Whether a experienced DIYer or a beginner, silicone sealant empowers you to handle a diverse range of tasks with confidence.

Installation Advice for Home Improvement Tasks

While using silicone sealant, preparation is key to securing a durable and lasting bond. Start by wiping down the surfaces that will be sealed, removing any dust, dirt, or old sealant. A clear surface ensures better adhesion and prevents any contaminants from compromising the seal. If you're operating in areas prone to moisture, like bathrooms or kitchens, also make sure they are entirely dry before using the sealant.

Subsequently, consider the deployment technique. Utilizing a caulking gun can provide greater control over the amount of sealant released. Snip the nozzle of the silicone sealant tube at a 45-degree angle to create a even bead. When applying fugenschmiede , move the gun steadily along the joint, ensuring even coverage. Strive to maintain a consistent speed to eliminate gaps or excessive buildup, which can result in a messy finish.

Finally, finishing touches count. After putting on the sealant, use a damp finger or a smoothing tool to refine the bead for a clean appearance. This also helps force the sealant into the joint, enhancing its adhesion. Allow the sealant to cure fully following the manufacturer's instructions before trialing it to water or stress to confirm optimal performance.